Non-Ferrous Alloys Metal Cast – Wide Range of Sandcasting and Centrifugal Casting

Industries Served by Nonferrouscast

The Vital Role of Metal Casting Across Diverse Industries

Metal casting is a cornerstone of modern civilization, shaping the world around us in countless ways. From the intricate components of power grids to the rugged equipment used in mining, cast metal parts play a critical role in numerous industries. This versatility stems from the inherent advantages of metal casting, including:

- Design Flexibility: Casting allows for the creation of complex shapes and geometries, catering to a wide range of functional requirements.

- Dimensional Accuracy: Modern casting techniques produce parts with high dimensional precision, ensuring consistent performance and interchangeability.

- Material Versatility: A vast array of metals and alloys can be cast, each offering unique properties to suit specific applications.

- High Strength and Durability: Cast components can withstand significant loads and harsh operating environments, making them ideal for demanding industrial applications.

- Cost-Effectiveness: Casting can be a cost-efficient manufacturing process, especially for high-volume production runs.

Industries Served by Nonferrouscast

Nonferrouscast finds application in a remarkably diverse range of industries. Here’s a glimpse into some of the sectors that heavily rely on cast metal parts:

- Power Grid: The reliable transmission and distribution of electricity depend on a robust infrastructure. BushBearing plays a vital role in this sector, producing components like:

- Transformer housings

- Switchgear enclosures

- Transmission line towers

- Busbars and conductors

- Turbine Industry: Turbines are essential for power generation, propulsion systems, and various industrial processes. Casting is crucial for manufacturing turbine components such as:

- Rotor blades

- Casings

- Nozzles and diaphragms

- Steam pipes

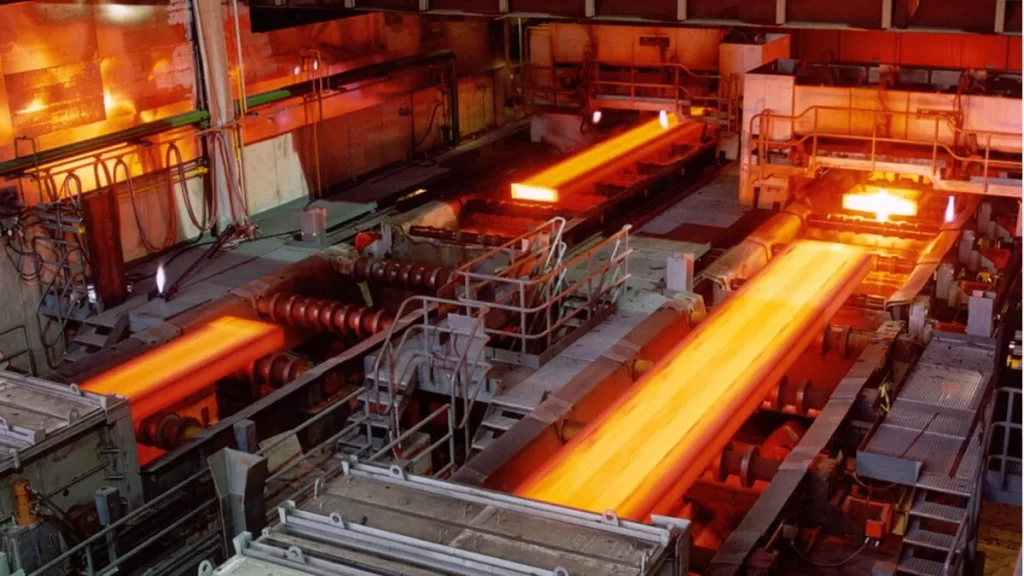

- Steel and Sugar Production: The production of steel and sugar involves heavy machinery and equipment that endures extreme conditions. Cast metal parts are widely used in these industries for components like:

- Rolling mill rolls

- Gearboxes

- Sugar mill crusher housings

- Conveyor system components

- Defense Sector: National security hinges on dependable military equipment. BushBearing is utilized to create critical defense components like:

- Engine blocks and cylinder heads for armored vehicles

- Missile bodies and launch tubes

- Firearm components

- Ship propellers and rudders

- Mining and Mineral Processing: Extracting valuable minerals from the earth necessitates robust machinery. Casting provides essential components for mining equipment, including:

- Crusher jaws and liners

- Grinding mill components

- Material handling buckets and chutes

- Conveyor system parts

- Automotive Industry: The automotive industry thrives on innovation and efficiency. Casting remains a significant contributor, producing parts like:

- Engine blocks and cylinder heads

- Transmission housings

- Suspension components

- Brake drums and calipers

- Construction Equipment: The construction sector relies on heavy-duty machinery to build our cities and infrastructure. Cast metal parts form the backbone of construction equipment, including:

- Excavator buckets and booms

- Bulldozer blades and frames

- Crane hooks and lifting components

- Mixer drums

- Oil and Gas Industry: Exploration, extraction, and transportation of oil and gas require specialized equipment that can withstand extreme pressures and environments. Casting plays a vital role in this sector, producing components like:

- Valve bodies and housings

- Pipeline fittings

- Pump components

- Wellhead equipment

- Railway Industry: The safe and efficient movement of people and goods across vast distances relies on a robust railway network. Casting contributes to the railway industry by providing parts like:

- Locomotive engine blocks

- Wheel hubs and brake discs

- Track components

- Couplers

- Consumer Goods: Even everyday consumer goods often incorporate cast metal parts. Some examples include:

- Pot and pan cookware

- Appliance housings

- Lawn and garden tool components

- Decorative hardware

The Future of Nonferrouscast

As technology evolves, Nonferrouscast continues to adapt and improve. Here are some trends shaping the future of this industry:

- Additive Manufacturing Integration: The rise of additive manufacturing (3D printing) presents exciting possibilities for integrating it with casting techniques. This can lead to the creation of complex geometries and hybrid components with unique properties.

- Advanced Materials Development: The development of new alloys and composites with superior properties will further expand the applications of metal casting.

- Sustainable Casting Practices: Environmental consciousness is driving the development of more sustainable casting processes that minimize waste and reduce energy consumption.

- Automation and Robotics: Increased automation and robotics will enhance efficiency, improve safety, and enable more consistent quality in casting operations.

In conclusion, Nonferrouscast remains a vital and versatile manufacturing process, underpinning countless.